EveraMOD Pump & Wastewater Lift Stations

The Affordable, Next Generation, Wastewater-Utility Infrastructure Solution

DURABILITY • CAPABILITY • AFFORDABILITY • ENGINEERING

DURABILITY

Built to Last

Durability is the most important EveraMOD design consideration. The Structurally Reinforced ThermoPlastics (SRTP) utilized in the pump station manufacturing process ensure that each station will have the utmost in structural capacity and an industry best continuous duty life cycle of 100-years. Wastewater Utility Owners can stop worrying about expensive future pump station replacements.

- Designed using 3D Parametric Modeling

- Structural Plastic will last 100 Years+

- Finite Elemental Analysis utilized for structural evalution

CAPABILITY

Designed for All

Applications

EveraMOD — a turnkey, complete Single-Point-of-Delivery wastewater pump station system

The EveraMOD Lift Station is for every wastewater utility that needs to pump wastewater. Whether it’s a commercial property, a clustered residential development, an industrial manufacturer, or a municipal utility, EveraMOD will provide affordable and sustainable wastewater pumping service for decades.

Commercial Properties

Residential Developments

Industrial Manufacturers

Municipal Utilities

AFFORDABILITY

Lowest Cost

EveraMOD addresses the most critical element of any major wastewater infrastructure installation — COST!

Our vertically integrated manufacturing approach and fast site installation permit the ability to deliver the most complete, technically advanced, and longest lasting package pump station in the world. This means lowest Initial Cost and Lowest Total Lifetime Cost of Ownership.

APPLICATIONS

Commercial & Residential

If you are a Site Planning Engineer or Real Estate Developer and need a Fast and Inexpensive Wastewater Pump Station Package, the EveraMOD Commercial Series System is for you! Designed for Budget-Minded Planners and Contractors, this Package includes the basic equipment needed to satisfy most local regulatory technical design standards for private pump station construction.

Municipal

Public Wastewater Utilities must provide continuous wastewater service without the fear of interruption and environmental impacts. The EveraMOD Lift Station with its Structurally Reinforced ThermoPlastic Structures, corrosion resistant internals, and advanced control systems will eliminate costly future infrastructure repair and replacement projects.

Industrial

Industrial Wastewater Utilities experience the harshest operating conditions. Wastewaters with extreme variations in pH related to corrosive liquids and gases quickly destroy concrete and painted steel structures. The HDPE and PP plastics utilized in the EveraMOD Package are perfectly suited for these applications and can be complemented with explosion proof and intrinsically safe systems.

ENGINEERING

Easy to Specify and Deliver

EveraMOD was developed by experienced Wastewater Engineers familiar with the daunting challenges faced by Consulting Engineers, General Contractors, and Utility Owners. Complete Engineering Document Packages including 2D CAD Drawings and Performance Specifications are available. EveraMOD is supported by a technical team well versed in how to design, install, and operate wastewater pump stations.

THE PROBLEM:

Failing Wastewater Infrastructure Systems

Mission Critical Water Infrastructure

99% of modern Wastewater Collection Systems rely upon concrete or masonry materials for structures such as manholes & wetwells

Constant & Expensive Maintenance

Wastewater Utilities operate under the harshest conditions. Concrete succumbs to corrosion & requires constant repair or replacement

Sustainability Challenge

Modern Wastewater Collection Systems MUST provide constant & perpetual service. Failing wastewater utility systems create environmental & public health issues

Contingent Future Liability Cost

Utility Owners fight a constant battle to provide cost effective service. They have been losing this expensive battle for the last century.

Human &

Environmental Impact

Failing Infrastructure Systems create an unbearable cost burden on the customer and the environment.

THE SOLUTION:

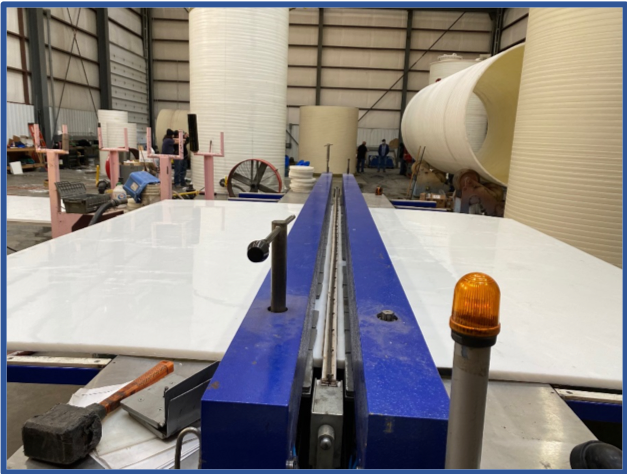

Heavy Plastic Manufacturing

Wastewater is corrosive and substantially reduces the service life for manholes and pump station wetwells made from conventional concrete. By using High Density Polyethylene (HDPE) and Polypropylene (PP) plastics, EveraMOD Pump Stations leverage the inherent corrosion resistance of these superior materials to create the world’s toughest and most durable pump station structures. This is the key to delivering a “Total Equipment Solution” to those customers who need this level of infrastructure performance.

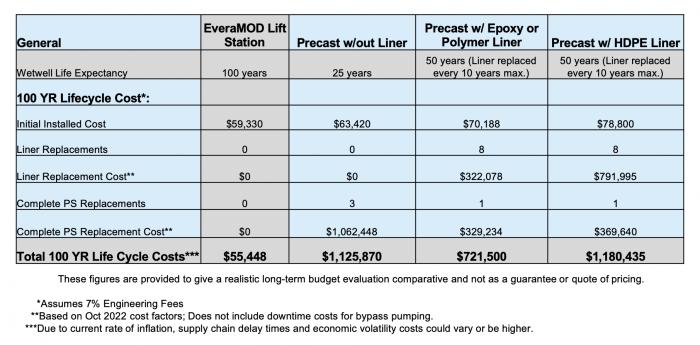

SRTP vs PRECAST

Concrete Life Cycle Cost Comparison (8’ ID X 20’ Deep Unit)

EveraMOD Wastewater Lift Stations

“A sustainable solution for every Wastewater Utility”

- Robust Structurally Reinforced ThermoPlastic (SRTP)

- No Specialized Coatings or Liner Systems Required

- 100-Year Structural Service Life (Corrosion Resistant)

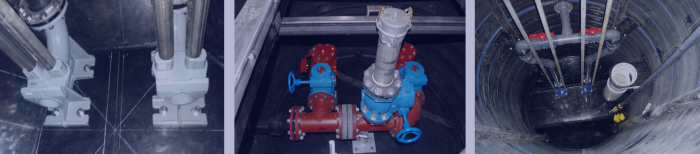

- Factory Complete Package Solutions including:

- Choice of Pumps (Grinder/Non-Clog/Chopper/Suction Lift)

- Choice of Piping Materials (PVC, HDPE, DIP, or SS)

- Control Systems with PLC, HMI, and Remote Monitoring

- Valve Vaults with Control Valves, Bypass Connections, etc.

- Grinder Packages and Meter Vaults

- Pump Hoists and Crane Systems

- Generator Systems with Auto-Transfer Switch Gear

- Standardized Designs with Customizable Options

- Lowest Cost with Fastest Installation Time compared to typical Pre-Cast or Cast-in-Place Systems

REMOTE MONITORING

If your Refrigerator has Internet Access and Remote Monitoring, your Pump Station should as well!

Wastewater Utility Owners need to know what is happening with their infrastructure systems. Remote Monitoring & Control is available, affordable, and provides real time access to each EveraMOD system. Real Time Status Reports, System Alarming, and Historical Data Storage significantly reduce operator labor costs while dramatically improving preventative maintenance.

Optioned for the End-User

Whether you are designing a new pump station or overseeing an existing pump station replacement, you can rest easy knowing that EveraMOD can be delivered with your choice of mission critical components. If you have a pump brand preference or a unique equipment standard, we can meet that need. EveraMOD can be equipped with a broad variety of equipment options.

EveraMOD Wastewater Lift Stations

Standard Equipment Specifications

- Diameters: 48”, 66”, 84”, 92”, 110”, 134”, & 156”

- Plastic: Polypropylene or High Density Polyethylene

- Hatches: Hinged aluminum (300 PSF load rated)

- Pump Configurations: Simplex and Duplex

- Pump HP Ratings: 0.5 HP to 150 HP

- Pump Discharge Rates: 10 GPM to 1,000 GPM+

- Pump Types: Grinders, Non-Clog, & Chopper

- Discharge Pipe Material: PVC, HDPE, or SS

- Control Panel NEMA Rating: NEMA 3 or 12R

- Level Monitoring: Float Switches or Level Transducer

- Back Up Generator: Propane or Diesel with ATS

- Structure Warranty: 60 month

EveraMOD Reduced Costs at each Phase!

Advanced Design Algorithms combined with 3D Virtual Design save time during Planning & Permitting Phases

Detailed Equipment Drawings & Installation Guide ensure fast and efficient construction at the project site.

Structural Plastic Materials and Fabrication eliminate corrosion and system deterioration while extending service life.

PLC based System Controls combined with Remote Monitoring & Control Reduce Operator Labor Costs

ENGINEERING TOOLS FOR YOUR CONVENIENCE!

- 3D Isometric General Configuration Drawings

- 2D Construction Documents

- Vendor Engineering Support

- Performance Specifications

- Installation Guide

- O&M Manual

EveraMOD UPGRADE OPTIONS

(Customizable when Required!)

Pipe Materials:

- HDPE (multiple pressure ratings)

- 304/316 Stainless Steel

Pumps:

- Explosion Proof (including Discharge Elbows)

Level Monitoring:

- Level Transducers

- Sonic Transducers

- Radar Sensors

Flow Monitoring:

- Electromagnetic

Control Panel:

- 304 Stainless Steel

- Arc Flash Protection

- PLC & Touchscreen

- Soft Starters/VFD’s

Emergency Back-Up Power:

- Propane (15 Kw to 100 Kw)

- Diesel (100 Kw and larger)

Structural Top:

- H-20/HS-20 Vehicle Load Rated Hatch

- Steel Reinforced Concrete Top (Design Only)

Valve Vault:

- Emergency By-Pass Pump Connection

- Check Valves and Control Valves (HDPE Materials)

Electrical System:

- Factory Assembled Racking System w/Roof System

- Main Disconnect

- Automatic Transfer Switch (when Genset provided)

- Surge Suppression Protect

- Sub-Distribution Panel

- Complete Weather Protected Building

SUSTAINABLE

Lowest Carbon Footprint

The structural plastics utilized in the fabrication and delivery for each EveraMOD system reflect LEED compliance for Water Utility Installations. With a Manufacturing Embodied Energy Quotient seven times lower than comparable concrete pump stations and a continuous duty life cycle four times longer, EveraMOD represents the future of sustainable wastewater infrastructure by conserving natural resources AND protecting the environment.

Modular Water Systems

Phone:

(323) 451-7050

Email:

Contact@modularwater.com

Design & Manufacturing:

Progressive Water Treatment

2535 E University Dr

McKinney, TX 75069

Contact Form

Email us with any question or inquiries or call us at (323) 451-7050. We would be happy to answer your questions.