EveraTREAT Wastewater Systems

Commercial & Industrial Wastewater Treatment Products

THE NEXT GENERATION

EveraTREAT is manufactured using ultra-durable, non-corrosive, high density polyethylene and structurally reinforced thermoplastics that have the unique capability to be installed above ground, partially buried, or completely buried and last a hundred years or more.

PREFABRICATED WATER TREATMENT TECHNOLOGY

Modular Water Systems™ packaged water and wastewater treatment products deliver the ideal combination of cutting edge wastewater treatment technology, masterful system design, thought leading — world class engineering and a whole new way of packaging and deploying water treatment machines.

They are innovative, compact, economical and have a lifespan of up to four times that of traditional concrete, steel or fiberglass systems. But above all, they are impressively effective in getting the job done.

Because Modular Water Systems use Structurally Reinforced ThermoPlastic (SRTP) materials and high-tolerance factory assembly under controlled conditions, our units will reduce both installation time and costs, as well as total lifetime cost of product ownership.

Our product line of wastewater management systems is an ideal choice for decentralized wastewater treatment in residential, commercial, agricultural and many industrial and municipal settings. Treatment capacities in our standard units range from the Modular 2,000-10,000 GPD and 10,000-25000 GPD standard compacts and 25,000 GPD up to 250,000 GPD in larger custom built units. Some applications enable standard units used in tandem for average daily flows of up to 50,000 GPD.

APPLICATIONS

- Industrial Oil, Gas and Chemical

- Power Generation

- Pharmaceutical

- Food & Beverage Manufacturing

- Agriculture

- Hotels

- New Development (Residential & Commercial)

- Institutional Facilities (Rural Schools & Local Governmental)

- Small Industrial & SIU Pretreatment Applications

- Custom Sub-Unit Process Upgrades for existing WWTP’s

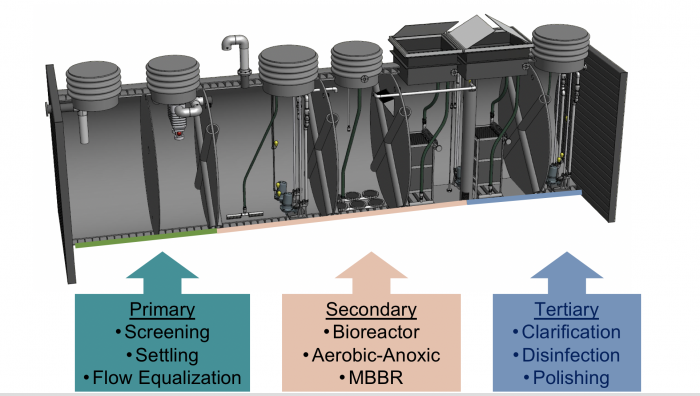

PROCESS

Proven Wastewater Treatment

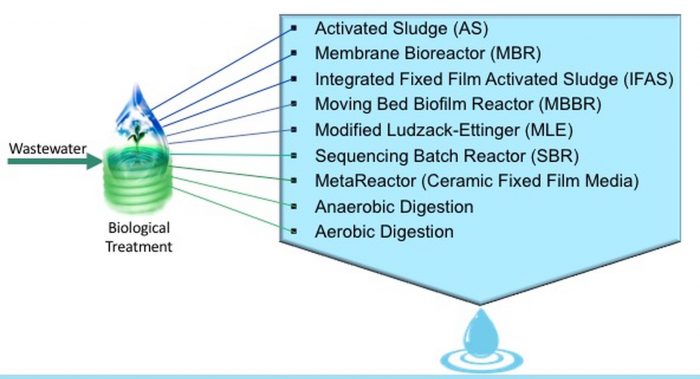

Spectrum of Biological Treatment

QUALITY

Modular Water Systems wastewater treatment products are designed by OriginClear’s Chief Engineer, Daniel Early, leader in next-generation, innovative, decentralized water machines and are part of the Modular Water Systems™ product line. The systems are fabricated and built by Progressive Water Treatment™ (PWT), our Texas manufacturing facility. PWT’s superior reputation, solid industry relationships and twenty-plus years of experience building industrial grade, advanced membrane systems are leveraged to bring the highest quality manufacturing and best vendor pricing our wastewater systems. We take pride in delivering the best quality at the lowest possible cost.

ECONOMICS

Better Economics For Owners & End-Users

Our standard packaged wastewater treatment products will reflect a total installed cost savings of 10% to 35% compared to mainstream, conventional wastewater treatment solutions. These cost savings are possible due to their materials, modular design, factory construction and being connection ready upon arrival.

Our factory-assembled units provide significantly reduced installation costs compared to traditional on-site, piecemeal constructions using concrete, steel or fiberglass, which take longer to design, build and bring on line.

A significant Primary Benefit of our onsite point-of-use modular products and systems is their inherent value-add that increases real estate and property asset value while boosting the owner’s Environmental, Social & Governance ratings due to compliance with responsible environmental stewardship guidelines. Concurrently they reduce corporate risk and liability through superior reduction of pollution and carbon footprint factors.

ENGINEERING SUPPORT

- Simple and effective preliminary design support.

- Detailed budgetary and final equipment proposals.

- Fully engineered solution development.

- Robust technical permitting packages.

- Detailed engineering calculations.

- 3D model design development.

- 2D CAD & pdf drawings.

- Performance specification in CSI format.

- Installation guide and O&M manuals.

Modular Water Systems

Phone:

(323) 451-7050

Email:

Contact@modularwater.com

Design & Manufacturing:

Progressive Water Treatment

2535 E University Dr

McKinney, TX 75069

Contact Form

Email us with any question or inquiries or call us at (323) 451-7050. We would be happy to answer your questions.