COO Tom Marchesello briefed us on what's driving sales and delivery to really take off… And no, it isn't by chance! And is seeing the beginnings we believe will become a tsunami of adoption that literally transforms the water industry. The real question is, can we scale fast enough to meet the demand? Find out in this video!

Transcript from recording

Opening

I'm Riggs Eckelberry co-founder, chairman, CEO of OriginClear. The government needs to continue to provide a lot of abundant clean water, but what happens to it after it's used when it's dirty? Do you know that 80% of all sewage is never treated, it's just dumped? That leads to water scarcity, but it also leads to a lot of disease and pollution of the ocean turning into something horrible.

The same time, the cities and counties are not getting the funding they need to really treat the water and so they can't keep up. The solution is let the people who use the water clean the water. Water on demand is investment in actual capital assets that earn income. Sign up to hear my weekly briefing every Thursday night. 5 p.m. Pacific, 8 p.m. eastern. Just put oc.gold/ceo in your browser register for the briefing and I look forward to hearing more from you.

Introduction

And welcome everyone to the CEO briefing. And I'm so happy to see you here today. It is Thursday, August 18th, and I'll put that up on screen shortly. It is briefing number 174. And of course, it's about Water is the New Gold. But specifically, I mean, you know, we like to say "Water is the New Gold, Water is the New Gold." Why? Because it's an asset. And unlike gold, it actually earns money. So this is a it's a beautiful thing.

So we're going to jump right in now. By the way, we're jam packed. I had a whole bunch of stuff about inflation and recession and this and that. Not this week. We have stuff. It's OriginClear specific, very exciting. So we're going to put all of that economic trend stuff for another week. Okay. Well, because we are the most transparent company, public company in America, I thought you could watch what the Board saw on Monday just prior to our second quarter filing. So I'm going to go ahead. You are the board.

Start of video presentation

Auditor Presentation to the Board

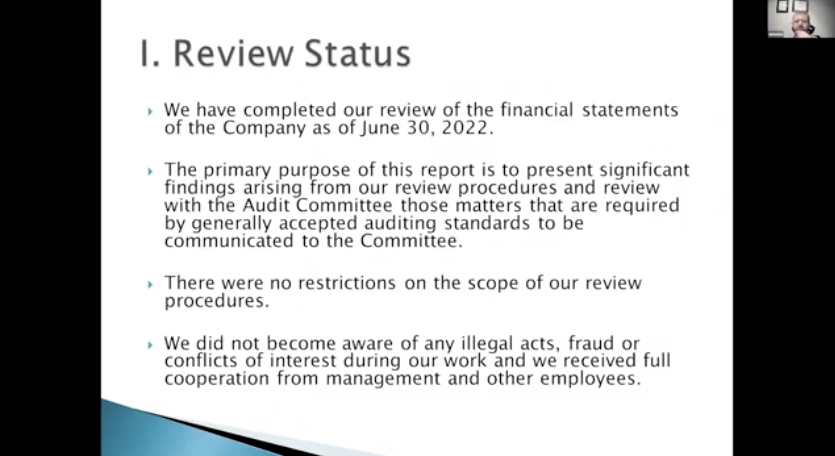

Casey: Okay. So we're at the finish line. In other words, no new critical accounting policies were adopted in the current period. The accounting estimates that are the largest estimates in the financial statements continue to. I'll go through this PowerPoint. That'll be easier for you guys that way. Okay, here we go.

So review status. I just commented where we're at. No restrictions on the scope of the work and we're not aware of any illegal acts, fraud or conflicts of interest during our, during our review. OK, I'm going to go to the next stage. Here we go. Just talking about the fact that we consider internal control, but we don't rely on internal controls for our testing. We do substantive testing.

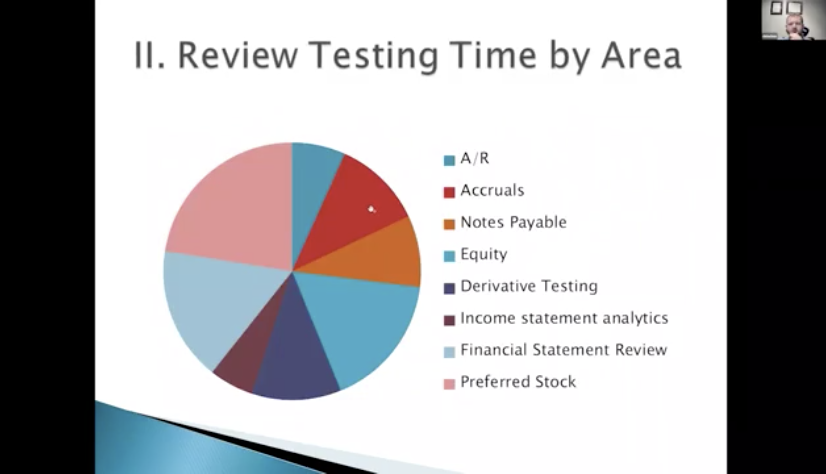

Also during a review, we do inquiry and analytics and then we do do audit procedures on areas that are more subjective, typically due to error such as new revenue items, derivatives, classification of preferred stock for you guys, things of that nature. We do all of that during the review so we can go on to the next slide.

You can see here is just a pie chart of the majority of our testing and you'll see a lot of it is preferred stock equity testing, things of that nature, which makes sense for this particular company.

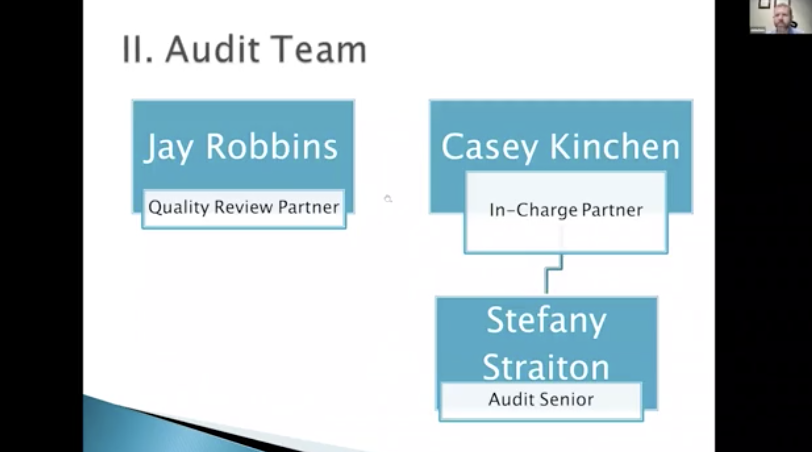

That's the engagement team. Been the same now for several years. Myself as the in-charge Stephanie as the Stephanie as the kind of day to day. She has a staff or two underneath her that helps her with the engagement. And then Jay independently oversees the entire audit process.

Results of the review: We're not aware of any material modifications needed to conform in GAP (General Accounting Principles). So that basically means we're at the finish line here. No significant new accounting policies were adopted or unusual transactions.

Okay. We just talked about not having new accounting policies and usual transactions, and we also had no consultations with other CPAs or auditors either. Add that to it. We're not aware of any errors or irregularities. The largest judgments and accounting estimates in our minds still continues to be the valuation of derivative liability, location of equity transactions. And then, of course, the allowance that would be necessary for AR.

Riggs: What are the issues that you see?

Casey: Don't see any issues. They're just the the key estimates that are inherent in the financial statements. So we require to discuss what we think are some of the larger estimates in the financial statements. So no issues with those other than they're just inherently complex areas in the financial statements.

Riggs: Okay. Thank you.

Casey: Yes sir. As I stated before, we reviewed Form 10-Q and is ready to go at this time and really positive response here. There were no review adjustments or no proposed pass to journal entry. So that's a really good step from where we were a couple of years ago. No disagreements with management, no consultation with other accountants, no major issues discussed prior to our our party, to our retention.

Riggs: In other words, this is not a marriage.

Casey: We provide no advisory services. If we were to do anything other than what we already do in terms of our attestation work as an auditor, we would get approval from the board prior to doing that as it could impact our independence. No deficiencies in the internal control structure and of course, no fraud, or illegal acts were uncovered. Just talked about the fact that we're independent and what would impair independence. Probably all I want to say about that.

And we're happy now to open it up to questions, comments, concerns. I usually read it from the 790 letter, so I apologize for my tardiness. But overall, I thought the accounting team did a good job. Obviously, we're here to file in. We had no adjusting journal entries. Also pleased to see revenue up for the company this quarter as well. So that's always positive. But I'll shut up now and take any questions or comments that the committee may have.

Anthony: You know, I usually like to ask some technical, but you've answered them all. What is the difference this quarter? Is it Prasad getting involved with all the esoteric accounting with these derivatives and preferreds and all that is is that's what I mean. We've been aiming for this for a long time and I'm.

Casey: Yeah, no, I think the Prasad has been a big help for the company for sure. I also think that everyone's just getting more familiar with the transactions and how they're accounted for. So I think the combination of the combination of those things and getting information to it a lot earlier, the accounting team, than what we used to get it in the past. So those have all been all been huge improvements.

Anthony: And the job. Excuse me? The job costing side?

Casey: Yeah. You know, the company has always done a pretty good job on the job crosting side and keeping up with their percentage of completion accounting. So I don't know that we've ever had an adjusted journal entry on that. We look at it real heavily at year end. We confirm with the customers at year end where they're at in terms of completion and cost that was incurred. But they've typically done a pretty good job in that area.

Anthony: It sounds good. Cool, that's really good progress.

Prasad: Just like to add something from my side in regards to the percentage of completion, we're actually taking it one notch up. We are now aiming for a monthly revenue recognition which we had missing because of lack of members. Right.

Anthony: Right.

Prasad: Relying on the external accountant. We do have a new person at McKinney, the full charge bookkeeper and also a contractor helping us out with tracking the job costs on a timely basis, but also tracking with all the material cost of invoices and everything. So this in fact will be our first month where we'll be reporting revenue on a monthly basis as well going forward. So that's definitely a significant improvement on our side.

Anthony: Oh, no, no, that's. Look, from an operational standpoint, that's a big KPI (key performance indicator). So they're kind of meaningless if you can't do them monthly.

Prasad: Right, exactly.

Anthony: And the fact that you're headed that way, that will make the quarterlies and the annuals way easier to do so.

Prasad: Absolutely.

Anthony: I applaud the the investment by the company and the leadership by you and Riggs and everybody else involved. So good. It's all good news from my perspective.

Prasad: Thank you.

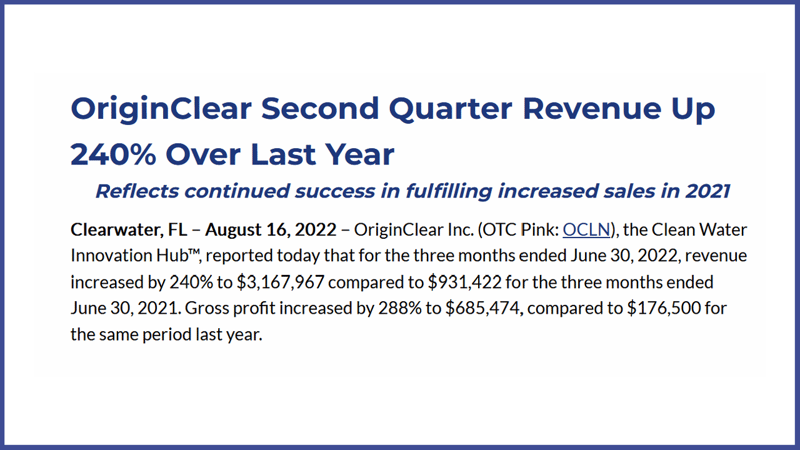

Riggs: So I do like the numbers that we're seeing. Second quarter revenue is up almost 300% over last year. We have a gross profit almost 300% as well from $176,000 to $685,000. That's very well, well done. Revenue for the half year is also up. Basically, we are we've now achieved in a half year what has been the standard for entire previous years. So that is good. Also, loss from operations is narrowing. Even though we continue to develop these new initiatives. So I think the fundamental numbers are looking good as well.

Anthony: Does that help with your financings, Riggs?

Riggs: No. PR. None of it.

Anthony: It, it's just a sales pitch. It's all you.

Riggs: No, no, no. It's actually, it indicates, we're not just aspirational, right? That we actually are doing something. But no, seriously, we. We doubled our sales last year.

Anthony: Yeah.

Riggs: Revenue was flat. And now, of course, revenue is catching up to that doubling and it's showing basically a doubling. So we're seeing an acceleration in sales. The one thing that obviously we got to watch out for is, we sell like crazy, deliver like crazy, and then we have to go back and sell like crazy. So, evening that out is going to be the challenge, but we'll manage our way through it.

Anthony: It's better than the alternative anyway.

Riggs: So yeah, Prasad is getting closer and closer to recognized revenue in real time. In other words, ten days after the close of each month, which is extremely vital to us.

Anthony: Yeah. Well, good.

Riggs: And I want to thank Prasad, Eric and the audit team for their help with this, it was extremely, Gwen Duffey. It was extremely smooth. There were no tears this time, which was good.

Casey: Yeah, I've had a couple of clients that have actually made Stephanie cry over the years that she's been with me. She's been for ten years now. You guys are not one of them. Please don't think that.

Riggs: I don't think we'd ride a client for long.

Anthony: I think Riggs was talking about himself.

Casey: We cry as auditors sometimes to believe me.

Prasad: And I'm sure Eric must be thinking that, "Well, guys, I cry. I just don't show my tears."

Eric: Yeah, I'll just, I'll just remain quiet here while you guys let everything go smoothly.

Riggs: Well, then, everyone, thanks to the board, any further questions before we wrap it up?

Anthony: No, I'm good.

Prasad: No, thank you.

Casey: I appreciate everyone's support and Prasad and the team, all the help.

Prasad: Thank you.

Eric: Thank you, guys.

Casey: All right, guys.

Anthony: Thank you.

Eric: Thank you all.

Casey: Thanks, everyone. Take care.

Anthony: Bye bye.

Prasad: Bye.

Casey: Bye bye.

End of video presentation

Postscripts

Riggs: Casey Kinchen, of course, was the lead auditor on the call, Tony Fidelio. He's really a very strong CFO. So he was the one on screen talking about the conditions. And of course, you saw Prasad with the similar background to what you see right now. So really great. And we're going to get into this issue of recognized revenue, by the way, a word that was used, KPI, key performance indicator that's very important and also gap generally accepted accounting principles. Those are a couple of abbreviations used just to get you up to speed on that.

And I will let Ken respond to Shannon Palumbo, who's got a wonderful question about investments, etc.. And I will be continuing. I am going to go straight into another video and we now have today's interview with Tom Marchesello about what we accomplished. So let's go ahead and get into it. Here we go.

Start of video presentation

Recognized Revenue Announcement

Riggs: All right. Well, hi, Tom. It's Thursday, the 18th. And this has been an exciting week as we have announced. We filed on Monday our quarterly filing. And I'm going to go ahead and share our announcement, which was that our revenue was up 240% over the same time last year. Gross profit increased 288% almost three times. And then on the half year, 155% increase and also gross profit increased.

And the important thing also that we always want to say. That we are continuing to invest in Water on Demand™, which creates a loss. But that loss has dramatically reduced by about 38% compared to the same period last year. So that's good news, too. The other thing that is not in this announcement somehow I'm not sure, is that when you look at the half year revenue, right down here, here we go, 4.4 million. That is literally more than the entirety of last year, which was $4.1 million in revenue.

So that's that's pretty stunning. So we are on track, though. The forecast for this year is that we'll do about 7.2. And I know it's hard to say what the second half will show for revenue, easier to tell what it'll show for sales. But this is pretty cool news.

Tom: Yeah, it's amazing. It's great. I'm very proud of the team, what the company has been doing. It's working hard and it's now showing.

Riggs: Well, you know, last year things kind of woke up in August when when we got the big utility sale, that $5 million utility sale. And it just accelerated from there. It seemed like from the middle of the year onward things just started revving up, both Progressive Water and Modular Water. So what do you think happened?

Three Factors

Tom: Well, I mean, it's three things. Number one, we got better as a company. We started doing our jobs better. We added new talent to the team that allowed us to produce a better product more efficiently, and then also reach out to our customer base and tell them about all our capabilities. And then they started ordering more.

The market itself picked up, which was great for domestic orders in the United States, where people were really seeking a US based manufacturer and producer of these piece of equipment.

And there's just a trend in place, I think, for the water industry and infrastructure industry, which is a prevailing topic, which you've been covering a lot with the administration and where the government's at. So I think these three things have lined up perfectly for us and then we positioned ourselves to where the hockey puck was going and now we're hitting.

Custom Build vs Standardized

Riggs: Well, Tom, you managed two very different businesses. On the one hand, Progressive Water is custom solutions. You know, what do you need? We'll do it. And they're incredibly good at that. In fact, three weeks ago, we were celebrating their 25th anniversary and they were already 17 years in business by the time we acquired them. So they've been around a long time. They have a reputation, but it's a very different business from Modular Water, which we launched in 2018. Which, we're trying to design to be very standardized. Right.

Tom: Right.

Riggs: So where I mean, what? Tell me a little bit about the challenges of continuing to expand Progressive as opposed to continuing to expand Modular.

Tom: Absolutely. Yeah. As you said, you know, Progressive Water had a very traditional business. So Marc's dad had run the business for 20 some odd years before then. Marc took on the second generation of it for the last 25 years. So you have 40 some odd years here, these guys in Texas doing this core water treatment business, right? With reverse osmosis and filtration business.

It's a very hands on business, very takes a lot of brain thought match with the hands on skill to make that equipment. And you have to think on your feet. Boom, boom, boom. Always trying to produce. So guys sought us out because we had that fabrication and quick ability to service.

And that business requires a lot of supply chain. You got to order the parts. You've got to then kind of keep finding the parts. You got to put them together in a real time. Test it out. Get it to the customer. And you're always continuing to do a couple of builds at a time, while, I won't call it inventing, I would call it troubleshooting. Troubleshooting can slow you down a little bit. Right?

And that business requires a lot of manual labor because there's a lot of lot of things that get assembled and welded and fabricated. So it's only going to grow so fast, constrained by how big is your facility? How many people do you have to do all that work? So that's an easy way to think about Progressive.

Now, that business, though, is healthy. It's a healthy business. It's a, it's a good industry to build. And it's, I would call it the core, reflective of how the old traditional industry was set up heading into this new wave of 2022. So it's, it doesn't change as quickly as maybe some of the new modern technologies like that's coming off the Modular Water side.

Riggs: So true. And of course, it's hard to get volume purchases of one specific item because it's so versatile.

Tom: A little too custom.

Riggs: Different kinds of things. But one piece of really good news is that we saw the consumables business grow to roughly, roughly $300,000 a month. June was.

Tom: Was great.

Riggs: $400,000. But the point is we're dramatically increased our consumables alone are roughly what we were doing entirely per quarter as a company not too long ago.

Tom: Right. Well, we made that choice. We wanted to push filters and membranes and screens and some of the consumable products that are easier, because then we order out of the supply chain. We then try to do just in time delivery. We're now getting into the position of being able to hold a little bit of inventory of some of those products as well.

When we get good deals, that allows us to get a little bit buying power and then we can have faster delivery out to the customer and then we become a go to place because they know, Hey, I can call these guys and they have that product, right, but they can get it for me. And that's kind of the easy replacement parts kind of business on consumables, which is great. We really want to be there. That's also allowed us to think about other things we can do that are similar.

Riggs: Well, what you're saying also, I think, is that it creates that ongoing relationship that lines us up for a potential larger project. Right. I mean, there we are. And then. Oh, here's an RO job. We were already supplying the reverse osmosis filters. Then we'll do the job, potentially

Tom: Right. Yeah. You want the tail, right? There's a long tail to this business. If I sell somebody a piece of equipment for 400,000 bucks, you know, I can sell them 20, $30,000 worth of filtration replacement parts per year and do that for ten years. And there's a nice recurring revenue model for us and we'll pick up our margin in there. But then the more I do that, the more I get buying power back to my supply chain, so then we can profit a little bit better over time.

Supply Chain Issues

Riggs: Well, before we move on to MWS (Modular Water Systems), I want to talk a little bit about supply chain. I know that there's some difficulties, but how well are we managing the supply chain issues?

Tom: We're getting better. Supply chain issues got very challenging over the course of the last 12 months. For everybody, it wasn't just us. But basic, basic parts from all the way, from materials, from steel to copper, got challenging and expensive to sourcing complex pieces of machinery like pumps. So pumps and electronics control packages got very expensive, very scarce.

Supply chain lead time went from 6 to 8 weeks, up to 16 weeks. I mean, these are massive differences in time. So it did put a lot of pressure back on us to have to order quicker and pay more, so neither of which we like. But that's the reality of things. We have just recently seen probably, the beginnings of a little bit of easing of that problem. Oh, good. But not a lot yet.

And I think for major suppliers and larger corporations, they are reporting that they're seeing a little bit of improvement, like even Tesla. Elon Musk reported they saw some improvement for some of the supply chain issues. It doesn't hit us yet because we're a small guys, but I think it's coming. I'd like to see some of it catch up. I think it'll take another year to work its way through.

Riggs: Well, and that really affects our ability to do what is called recognized revenue, right? And for our audience, that doesn't know what it is. We might make a sale, it's $1,000,000, but we can only recognize it as revenue as these milestones are attained. So first, 10% comes in. We deliver what's required for that 10% like some drawings, let's say right now, we can count that 10%.

And but now you're stuck with a machine. Let's say you're at 60 or 70% machine in the shop. It requires a part to then get that next milestone. And you're waiting. And that recognized revenue is held hostage, which is why it's so amazing. We got almost triple of our revenue this year. So it's stunning. Really.

Tom: Yeah, it definitely you're spot on as to how that how that process works. It is good that we did have so much success. We had grown our sales pipeline and knew that we'd have to do multiple projects. The way we hit that is we ended up with a lot of projects running concurrently.

So normally we would have had the shop floor kind of doing a batch of a few machines out the door. Then the next batch. This time we had about double the amount of machines being built on the floor concurrently, and then they were just some of them were just waiting for parts than to get out.

So what we did is we were holding the products build a little longer than usual to be able to book in enough of it while we waited for some of the parts and then putting them together as the parts came in and then getting them out the door. So it was a little unusual, but we just managed our way through it as best we could.

About Modular Water Systems

Riggs: So parallel action, I'll tell you, that's very smart. Well, excellent. Now, let's just turn to Modular Water, which we know is a different sort of business. We've got basically four products. EveraTREAT™, which is in ground EveraSKID™, which is containerized, EveraBOX™, which is the equipment buildings. And finally we have the EveraMOD™, which is the pump stations.

Tom: Yeah.

Riggs: And so what's happening with all those lines of business and how are we doing?

Tom: We're doing really well. So on the Modular Water side of things, that was kind of being led up by Dan Early, our genius engineer. We put a big team around him. Actually, a small team around him that actually had a couple other engineers and production guys and project managers. So we could continue to build out that core.

So we took our standardized designs, we really finished up all that, and then we basically made improvements to them and in pricing improved our margin on those. And then we took the whole thing and started presenting it more to our network of our reps as well as our partners, showing them what these standardized products can do.

People love them. They are like, just like, wow, these are amazing. This is exactly what we're looking for. The sizes are right. The pricing is excellent and the quality is there. And now the guys are able to build these machines and quote these machines much quicker. So now we're having much faster turnaround and responsiveness to everybody so that we can produce more of this product line over and over again.

And they're, they hit the same general size and configurations because they're standardized. So there's a lot less thinking on our end as to engineering it. always have to figure stuff out. A lot less brain damage, so to speak, and now we just basically go and execute. So now we're into execution mode on how do we do this and scale it.

Riggs: Well, I was talking to a potential partner that, actually what they are, is that they're in the energy business and they do water stuff on the side, sort of as a combo. So they try to delegate the water.

And I was telling them, look, it's kind of cool that we have this auto-configure software that is invested in tremendously. So that because these are standardized designs, plugs in the numbers and it pushes it out, but even that requires somebody putting numbers in and so forth. So let's give a shout out to some of the people we started with. Robb Litos, who was came in, what, a year and a half ago, something like that I'm thinking.

Two years ago we brought Robb in. Robb has a long relationship with Dan. Was an independent contractor. We brought him in under the Progressive side of things early, and then we moved him over to the Modular Water team so that it's him and Dan were really making things happen for a while. Yeah, absolutely.

Riggs: Now we added to it. We've got...

Tom: Mark Mazeket.

Riggs: Mark Mazeket who was showing amazing, really thorough work that I'm seeing out of him. Right?

Tom: Yeah. He's an amazing engineer, had tremendous industry experience and was just perfect for our product line. Like just really understood the wastewater treatment environment and the lift station environment's. Just very detail oriented guy, fast worker, smart, good process, really enjoyable to work with, with the customers and on the phone. And we send them out for deployment activations as well. So he's very versatile, very capable man.

Riggs: And who else is coming into the picture to help Dan?

Tom: We have Bill Maynor coming now. I just, he accepted his offer so he'll become a permanent employee with our team as well. He's been working with us in a consulting capacity for some time. Again, industry veteran, very talented and he has really good I would consider it project management as well as customer engagement skills.

So he's going to be very critical for us to tap into some markets and also explain what our products do and get them done. He's helped me with one of my toughest projects recently. I've been actually working with him direct on trying to get some really challenging projects completed. And he is, he's the kind of guy who rolls up his sleeves and just gets out there and does it. Really impressive.

Expanding Rapidly

Riggs: Well, I mean, you know, as we announced our the May sales by Modular Water were the equivalent of the entire last year. And so all of a sudden you've got more than ten X increase in business for Dan. And frankly, he was getting, he was turning into a bottleneck, right?

Tom: Yeah. It's like you never want to see anybody struggle because we're growing so fast and we didn't have enough support around them and that was happening. So it's like when some customers are saying, "Hey, I can't get a hold of Dan Early for two, three days,." You know, and then it becomes like four or five days. You're like, the reason is because he's working his butt off on, on the work, right?

So then I'm running some interference and then I got to start assigning the projects down so the new engineers I hired. So, it just took a little bit to kind of unclog it a bit, reset some process, and it was more than just people. We had the people and then two processes really made a massive difference.

One of them was the hire you made for Prasad on the finance side, who's really stepped up and made tremendous differences. Now we've added the extra accountant, a new process for building an invoicing and all the QuickBooks stuff. That's awesome. That helps a ton. And then the other side of things was the process we put in place just with the team.

So we have new project management tools, new toolkit checklists we have using different collaboration tools as well as our sharing folder systems. So now the team itself is actually running their project better.

The financial side of it, like knowing how we cost our parts and get our supply chain got a lot tighter so we can do procurement better. So all of that stuff really connects now from the moment of making a sale to then getting it booked and then ordering your parts and then getting it over to production.

And in that space, if you're not doing efficient business, it becomes a bog and you can really get caught up and just details that just will hound you. So now we're working our way through all those processes and we go back and we recycle and we try to make the next cycle better than the last and lessons learned. So the team gets together and discusses what we need to do. We also do a little review on hey, why did that go good or bad? Then let's let's do better the next time.

Pump and Lift Stations

Riggs: That's really great. Yes, the finance, Prasad Tare coming in, gosh, almost 18 months ago now, really making a big difference. David, over in accounting is proven to be very, in addition to the existing team, but I think that's really starting to make it all come together. I wanted to spend a few minutes not to take this too long, but I want to discuss the pump station business and where, why they think that's great and where it's going.

Tom: I love the pump station business. Honestly, it's one of the most exciting, awesome product lines we have for something so simple, right? It's like, it's funny because as technology guys that really like things, you think of pedestrian style technologies. Oh, that's so basic. The telephone was so basic. And then now we look at our smartphones and like, Oh my God, smartphones!

Pump stations, kind of the same way. They're like, water went into a hole in the ground. Stormwater drain, right, is a hole, right. But then it became a tank system buried in the ground. And now a live station is a tank system buried in the ground with a pump in it and some treatment on site. So you can treat the water right in that moment and then move it on its way. So now that's the pump station, lift stations.

And in the materials is made out of isn't just old concrete, which gets corroded now it's made out of high density plastics. It's environmentally safe. It's easy to install. Now you have a complete change to the way the industry can do this ubiquitous thing, which are these little station pump stations which go into hundreds of thousands of locations.

This is the kind of thing that's everywhere. You drive down a road and you see stormwater going into some basin or underground, it's going somewhere and often it's going into a lift station or a pump station.

You don't necessarily recognize it yet, but if you look into any city planning or any infrastructure planning, especially around where new developments coming, they've got to lay all this infrastructure in place and then they can build shops and homes and all the stuff around it.

Millions of Installations — Many Need Replacement

Or if they're going back to rebuild anything, old infrastructure, they can replace all these things. What we found was any city at any moment in time is dealing with at least a thousand lift stations, just in their town. And then you multiply that across all the places that are doing it.

Riggs: It's millions.

Tom: Millions of these things, right? So we have one city in Kansas which you know, we had a partner out there that was dealing with literally tens of thousands of lift stations and pump stations, of which there are thousands earmarked for replacement, thousands of them because their old 30, 40, 50 year old. And they need to be replaced.

Riggs: What happens when they get old?

Tom: They break and they leak. And then they basically the way they had to do it was they had to dig them out. And in big hole they have the repour concrete, wait for it to set. Then try to do all the connections again. Or they have to do two holes at once. Old one, new one. Now it's like, No, no, you don't have to do all that. You don't have to be four to six weeks on site. You can be three days on site and you can just pop a new one in. Right. That's a big difference for them.

Superior Product and Inventory

Riggs: Like as a sleeve, basically.

Tom: Yeah. So this is a big difference. And so we're customizing sizes that work as quick replacement parts and those types of environments that allows us now sell for at a time not one, because I can produce 4 to 8 at my factory, get them on trucks roll of the site, I can even have some in inventory. And now I've got quick supply chain for this critical piece that causes a lot of problems in the real world. So it's a really interesting thing.

What made that happen was our modular kind of concepts of pre fabrication, pre designing, standardization, you know, then where this goes, where this goes is exciting because now, as I said, we're going to make small batches, right? I already figured out supply chain with our preferred vendors. I got our plastic supply done. I know how to get my things up fitted.

Now what I do is I'm in the process of just starting an inventory stocking program right, now available right? Because I want to be able to supply these quicker. That gives us the ability to produce better with better margin, because I'll do a few at a time now, inventory them so I can supply them to the market faster.

So once people learn about that, they're going to be really hot on us. So our our sales should go up faster because they know we got them and we're going to be a preferred vendor because when towns and cities and corporations start specing a product, they then name us as a preferred vendor.

And now they know they can reorder from us because it's already been through their engineering departments for approval. So when they did one, now they can do ten. Right. So it's an easy thing. So one of our clients who has hundreds of commercial retail locations already has put a few in, and they're talking about doing 100 more. That's a lot. It's a real good number.

Automation and Improving Efficiency

Riggs: Because the thing that kills our margins, of course, is the amount of time we spend configuring the deal and talking to the client and going through the permitting and deciding if that turns into a highly automated. Here's the spec. Bada-bing bada-boom. All of a sudden with all that staff, time is dramatically reduced. Not only can we do more, but we're making more money on this job, right?

Tom: Right. And it makes it easier for everybody because then you're repeating tasks so you get better at the task. You know, nobody wants to invent on the fly, right? It's okay to make small customizations, some sizing changes and horsepower changes. Nothing too complicated, but to redesign an entire thing from scratch or have to do custom builds. That's time consuming on the engineering side.

Plus you have some risk of whether it works the way you think it's going to work in the real world versus when you stamp out a standardized product. You know it's working and now you make incremental improvements to efficiency or certain parts on it so that it just gets easier and better to manufacture, more cost efficient, more deployable, and then you start moving into deployment.

Asking the Right Questions

So when you start thinking about, How efficiently can I deploy something, how well can I put it in the ground? How well can I provide service to the customer channel? How easy can I make the job for the engineer who's on site and for the sales team who sold it? How can I make them more money and be more profitable to the guy who bought it from me and does the job on the ground?

Now you're asking all the right questions that are business, questions that really matter to scaling, because now making this a profitable business for my dealerships and I'm making this great for the distributors and for the guys who do the the pumping halls and the trucking, because these guys do it everywhere.

And they're going to, when they have a good experience, they're going to be like, "I love working with OriginClear. I love working with the EveraMOD system. I want to do that again." And then the older more. And that's really what we're getting ourselves into.

So we're going to have to improve some customer service because now we'll have to do some account management improvement as well because we'll have to deal with the volume plus managing the supply chain as well for those guys. But that's a good problem to have.

Loyalizing Channel Partners

Riggs: That's a version of Happy Wife, Happy Marriage. Your channel partner is happy. All of a sudden things start to really work. If they make more money, know, obviously people go where the money is. I wanted to briefly discuss for both PWT and MWS, is your new business channels. We're doing really well, I guess with manufacturer sales reps who know who we are, what we're good for. Right.

Tom: Yeah.

Riggs: Who else is giving us business?

Tom: The consulting engineers who we've traditionally work with, these are guys that are doing the project management engineering. A lot of civil engineers, environmental engineers, they're really bread and butter for the industry. Specifiers, they'll go in, they'll be on a project site or be working with the developers or the facilities managers, and they have a general idea of the engineering requirements at that site.

And they're always working on what the water quality condition requirements are for their municipality. So they have a lot of the detail about what we require in order to get that final spec back with the equipment. So they're they're very good at their jobs. If we make their jobs easier with standardized packages, it's a headache off their plate. They feel good about it.

More Than Enough Business

Riggs: Yeah. I mean, one of the beauties of us is, of course, that we are specked in our design is locked. So it's hard for anybody else to steal the business, which is good news.

Tom: Nobody wants to steal the business. That's the interesting thing. They just want to do the business. Like it's a weird way of explaining it. Like, Dan, I actually did a calculation on this. There's a couple other vendors who do some similar kind of things. If you took everybody and lined them all up. The ability for all of us and our competitors to meet the demand that the market has. None of us could do it.

Riggs: Wow.

Tom: None of us altogether. We couldn't meet the requirement. There's that much business out there.

Riggs: That is stunning. That's really stunning. Well, that's this is some really great news.

Establishing and Professionalizing Business Units

And I love the expansion of securing. I love how Dan and you have invested in multiple fabricators. So that unlike Progressive, which builds everything in one place, you potentially have a manufacturing network, internationalize it. This could be fun.

Tom: It could be fun. So when you're working with Ken and the team to kind of like professionalize the way the investment's working to connect it to doing a spin off, it's not just about the spin off. It's about establishing and professionalizing the business unit around the product line. Right? Because the product line for pump stations has a different business cycle and sales cycle that's a little different than water treatment side on waste or drinking water systems.

It goes faster. It can also be placed into third party manufacturing partners, I do a lot of my work, not just in my facility, but also in others. And in order to scale a business, I'd want to regionalize it a little bit, because if I'm supplying Kansas or Atlanta, I can have a facility that makes my equipment closer to my end destination so I have less distribution travel point.

Versus, if I need to do things in Seattle, I'd probably go find somebody up in that region to supply that market. Right. There's no reason to take something and build it in Tennessee and then drive it all the way to Seattle. Right. So instead, I'd rather have two third party manufacturers working with me who can make the equipment, and then it also lets me scale twice as fast.

Local is Healthy

Riggs: It's fascinating how not too long ago we would have gone, Oh, we've got to set up manufacturing in China. That's gone. Everything is local. And that's an amazing, amazing trend. And I think it's healthy.

Tom: It's healthy and it's the right thing to do because the truth is manufacturing coming back to the United States to service these opportunities. But it's also really about core competency. You know, there's a lot of discussions about did anybody lose their edge, so to speak, in core competencies of manufacturing when we got into this trend of outsourcing to China or India.

And sometimes you could say, yes, because we maybe didn't build a generation younger than ourselves who knew how to manufacture domestically the right way and keep an eye on it and care. The water industry has a lot of older gentleman in it who are phasing into their sixties now they're in their 50s, 60s, 70s. There is a new generation coming in that's in their thirties and forties, which is nice. They're eager to learn how to do things the right way.

There's a tremendous amount of manufacturing capacity out here in the United States, whether it's folks who do metal bending or welding or plastic extruding, all the different things that go into fabrication of these pieces of equipment, huge supply chain available. And there's large companies that actually have great history supplying things.

Sometimes we say, Oh, we compete with General Electric, but I think sometimes, no, I buy some parts from them. Right? So either supplier, right. You've got to just rethink who your partners are versus your competitors. Like there's a whole new wave taking place or rethinking who are you competing or are you collaborating? And I really think we're collaborating. It's a different, different market.

Future Expectations

Riggs: Well, it's this is all great to hear. I can tell you got your challenges, but it looks very optimistic. Tom, I really appreciate the hard work you're doing. I know that you're driving. You're driving the day, as they say. But you're building a great team. I love the quality of what's going on. I'm super bullish about the balance of the year. And then 2023 is a whole new game, right?

Tom: Absolutely. I think this year I'm really solid about where we're heading and what we're doing. It's been pretty consistent and next year it's so much opportunity for us. I'm kind of excited about it. Plus, I really think some of the market forces that have been strange that you talk about on the economic side, hopefully we'll have a little bit of clarity to that next year. And I think once some of that goes away, it eases people up and I think they're just more excited to do more business.

Riggs: Well, with that, I really wanted to tell you that we appreciate what's going on because it makes our job easier in terms of creating all these launch schedules for all these ventures that we're doing. So thank you, Tom. And just keep touching base, OK?

Tom: Absolutely. Have a nice day. Have fun.

Riggs: All right. Thank you, Tom.

End of video presentation

About Recognized Revenue

Riggs: Well, that was a lengthy but I think really, really enlightening discussion with the day to day guy, that chief operating officer Tom Marchesello. Now, there's so much content and I have to say that, frankly, we're not going to fit it all in. So I am going to jump back into the PowerPoint. So really fast. I'm going to cover a couple of things here. One of the things is, is we talk about this revenue thing.

What is revenue versus sales? This is a financial accounting standards board. And what they're talking about here is best shown in a chart that I created where contract is signed. And this is a sample payment schedule. And as you can see, we can only recognize, let's say it was $1,000,000 project. Well, only $50,000 can be recognized with the PO and 10% with the piping and instrumentation diagram, etc., and on and on and on. And that is the challenge of revenue, right? And what is called revenue recognition. I'm not going to go too deep into it.

Live from Coalwood, WV

I have a very short three minute video that Dan shot this today, this evening I'm going to play. There is a very, very good update on Water on Demand, the pilot which we're going to have to push to next week. But let me go ahead and play. This is the town of Coalwood, West Virginia. And let's catch, Dan, doing his thing here.

Start of video presentation

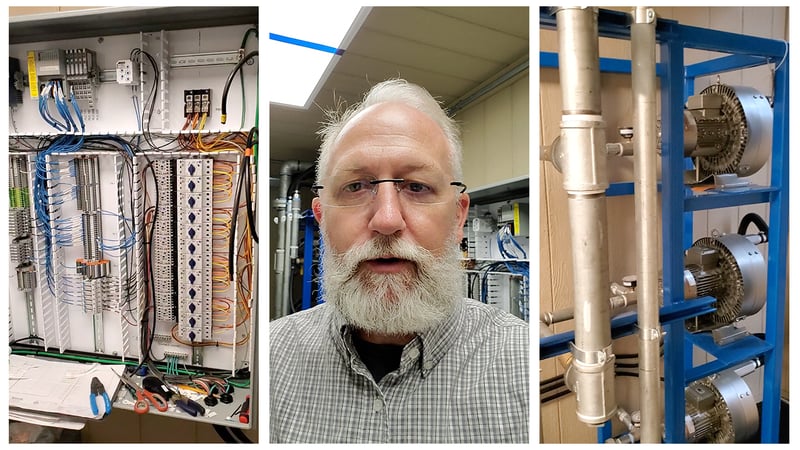

Dan: Good afternoon. This is Dan Early chief engineer with OriginClear and Modular Water Systems coming to you live from inside one of our latest EveraBOX, modular equipment buildings. This is where a customer of ours that we're soon to deliver. A complete package of EveraTREAT wastewater treatment system with our modular equipment building is scheduled to ship that out here in the next week or two to to the contractor that's going to do the final installation at the project site. Just want to just share a quick walkthrough.

I'm going to show the audience what the inside of one of our modular equipment buildings looks like. And this is a larger, bigger brother version of the EveraBOX unit that we just recently delivered for the Beaver Falls Municipal Authority customer in Pennsylvania. As you may recall, we just did a press release, an announcement on that, and that was a system, a much smaller system, about a 20 foot long, structurally reinforced thermoplastic building.

And this one that what I'm in right now is going to be a much larger version. This is our 40 foot building, and this one's kind of unique and that this building actually is compartmentalized. It means that it has multiple rooms in it. We have and I'm going to flip the screen around and do a walkthrough, but here is on one side we have our modular equipment building with its office space.

This is the space where the operator will function on a daily basis. It's got a service sink, lab sink. We have all of our supply cabinetry. Actually, this is an HVAC air conditioned space with that PTAC unit through the wall. And this gives the equipment facility the ability to use a modular factory assembled equipment building as a complement to their wastewater treatment package.

This avoids building the sticks and bricks custom erected wastewater treatment plant building at a facility much more efficient, much quicker, very fast delivery, very rapid installation. And it's an integral component to our wastewater treatment systems. So what you'll see, you'll see some of our aeration skids, some of the technical equipment used for the wastewater treatment process, the electrical control panel, it's in its final state of sub assembly or final assembly and emergency eyewash station, courtesy sinks, chemical feed systems and that type of thing.

So this is very typical of what you would see when we ship out a Modular wastewater treatment facility. It would be the influent lift stations, it would be the package treatment equipment, tank systems and the modular EveraBOX equipment system. So a quick walkthrough. Again, as I mentioned, this one here is probably within about three or four days of being complete and it will be shipped out to our customer in West Virginia.

End of video presentation

Coming Soon

Riggs: So that is a 17,000 gallons per day system. And what we're talking about here is this EveraBOX, which there'll be more about it next week. So stay tuned. And in fact, I'm going to tease you on this Water on Demand update, which I'm not going to show you, the commercial pilot update. Next week we're going to cover forever chemicals. Remember that we have a system that takes care of the forever chemicals. The dramatic situation with drought in the US and Europe, the Rhine running dry, which is ridiculous.

Dan says, I just shot two more three minute clips. He's got a US automotive assembly plant, an international government installation and a power plant, water cleanup system, and also a walk through with these 10,000 [gallons] per day (MBR) membrane bioreactor units for a housing development and a mobile home park. So we'll see you next week on that. And that is all I dare cover today. Ken, let's bring you in to wrap it up.

Incremental Improvements

Ken: All this business near my house, we've got the we've got the car dealer in Cranberry. We've got we've got Beaver Falls. About 15-20 minutes past that.

Riggs: Coalwood, West Virginia is a bit farther away.

Ken: Yes, it is. It's it's about 2 hours. Look, so here's so here's what in listening to Tom now, again, I'm the kind of the scientist mind here you're hearing the formation of the system changes and those those small, Tom described them as incremental improvements in efficiency. This is what companies like Amazon did in the beginning. Right.

First they were you know, they were shipping stuff very expensively. Then they started to develop their own fleet of trucks.

We've gone from a company that had an idea on how we could change the water. Business to implementing. Now we're actually working on improving how we're implementing. I think what's really exciting is to have that, to have that inventory of shelves. The ability to deliver like that is amazing.

Importance of Inventory

I walked into, my wife's lease is up and I walk into a dealership with money in hand, and they only can get me because of supply chains. "Because we have, we can sell you the car you don't want for twice the money, though." I was like, Oh, really, promise? But the point is, is I left that place without a car. Right. So it's not only having a superior product. What Tom didn't mention and I know you have, is serendipitous nature of that. High density polyethylene is not going through these terrible supplies. This is a locally sourced product.

Riggs: It's a very low tech product. And you're right, that polyethylene and polypropylene are are do not rely on China or anything like that. It's killing our competitors fiberglass, steel and to a lesser degree, concrete because it has bigger problems.

Ken: So make the natural partners say you guys are your guys are allowed, you can play, just come in and adopt our technology and that and that is the that's that beginning that domino effect of scalability that that we we aspire to. So that's exciting.

Riggs: And I'm actually being more ruthless than that. We're just going to kill them.

Ken: Okay. That works, too. We got Scarface over here.

Riggs: Exactly."Meet my little friend!" So what we have is, is we're starting to create national accounts, right?

Ken: Right. Exactly. And they're going, no, we want the other guy right. They,re jumping. my understanding is that we want to get to a place where they're bypassing the bidding process. So, we already know who we want. We already know who we want. Right. And I think that that becomes, that's when truly you get a change.

Call Ken

Riggs: With that we're up to the, we don't like it over an hour. So to talk to Ken to schedule a call oc.gold/ken, we have a ton next week. Like I say, Water on Demand commercial pilot that is already recorded. The update on that we will have to push to next week.

And I've got more from Dan. We've got more on our Clean Water initiative, which is growing fast. It is probably the fastest growing new product area of ours. I'll tell you, there's so much news. And of course, we're going to discuss the terrible state of water stewarding, stewardship in North America and Europe. So that is what it's all about.

Ken: And Shannon, Shannon, who talked to us on the chat. Shannon, you had the link there oc.gold/Ken. So my, my staff will get you on my calendar a.S.A.P.

Riggs: Wow. Well, everyone, thank you so much for joining. It's very detailed. I know that it got into the specifics, but this is the water industry. And you can tell that so much is coming together. And I appreciate your patience. So many of you stuck around till the very, very, very end. So thank you. It's been a wonderful briefing. Please show up next week. We're going to have much more exciting stuff to continue. So thank you, Ken.

Ken: Thank you all.

Riggs: We'll talk soon.

Ken: Bye bye.

Register for the next Insider Briefing: HERE

%20250px.png?width=250&height=53&name=OriginClear%20Logo%202019%20(RGB)%20250px.png)